Poole Harbour South Quay - New Port Facility

Byland Engineering prepared conforming and alternative tender designs and then assisted Bam Nuttall Limited in negotiating a contract to design and construct a new 200m long x 40m wide tied-back steel combi-pile wall for the Port of Poole. The structure, which is nearing completion in early 2018, provides a new docking facility for a variety of commercial and leisure craft. Available draught at MHWS is 11m.

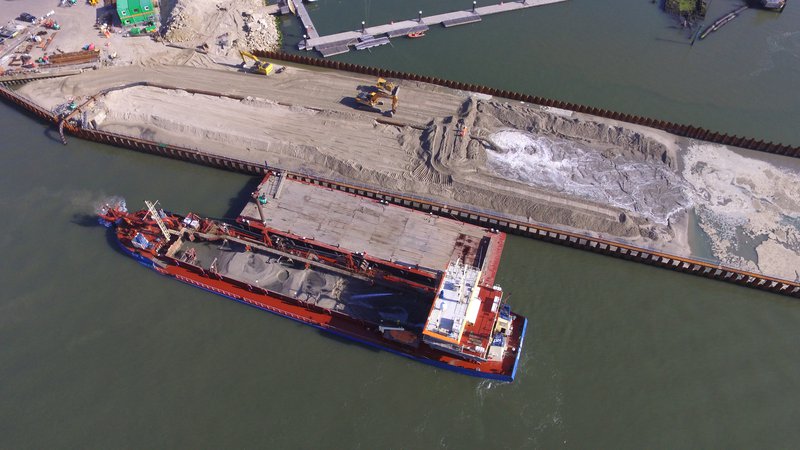

Quay approaching structural completion

The Byland service comprised advice and specification of additional overwater ground investigations, interpretation of the findings, detailed geotechnical modelling and analysis and the structural design and specification of piles, tie bars, waling beams and capping beams. Byland also prepared specifications for dredged sand infill and the layout and specification of a sand densification trial.

The wall is formed of ~20m long 880 MB HZ section high yield steel king piles restrained by 72mm to 85mm diameter passive steel tie bars. Between the HZ sections, ~14m long secondary AZ section steel sheet pile infills are used. The wall retained height is about 14m.

Dredging out of very soft compressible recent clay, silt and peat was undertaken by Poole Harbour Commissioners in an advance enabling works contract and this was quickly followed by placing of an underwater bund to about 3m below MHWS using sand dredged from the Swashway - the sea entrance to the Poole Harbour. Marine piling was then carried out from floating craft using vibro-drivers and drop hammers. Crucially, a large heavy duty 40t steel piling frame suspended from temporary driven steel tube piles was employed to ensure pile installation accuracy. Selected HZ piles were dynamically load tested after installation to verify their vertical load resistance.

Marine piling frame

After marine piling was complete and the "box" of the quay closed, internal filling, again using dredged sand, this time brought ashore hydraulically and then stockpiled and spread using back-actors, was undertaken up to tie bar level, just below MHWS. From here, internal steel sheet pile anchor walls were installed in dry conditions. Tie bars, connecting the perimeter combi-wall to each other or to internal anchor walls as necessary were also installed while the combi-wall acted as a temporary cantilever.

Hydraulic placement of dredged sand infill

Reinforced concrete capping beams up to 2.3m tall were then cast-in-situ upon the perimeter piles following which sand fill was placed, spread and densified using a purpose designed and built 15m long finned steel poker and pile vibrator suspended from a duty crane. Fenders, bollards, lighting columns and other port furniture is fixed to the capping beam. The steel piling is protected by a sacrificial aluminium alloy anode passive corrosion protection system.

Densification of sand infill

The first ship to berth at the new quay arrived in January 2018 after final dredging in front of the sea wall was completed. This latter operation was carried out by use of a long reach excavator.